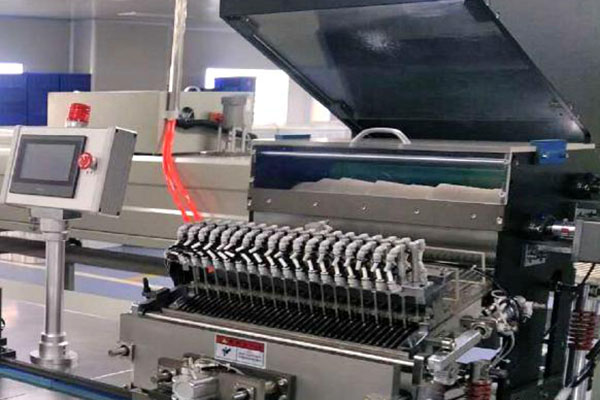

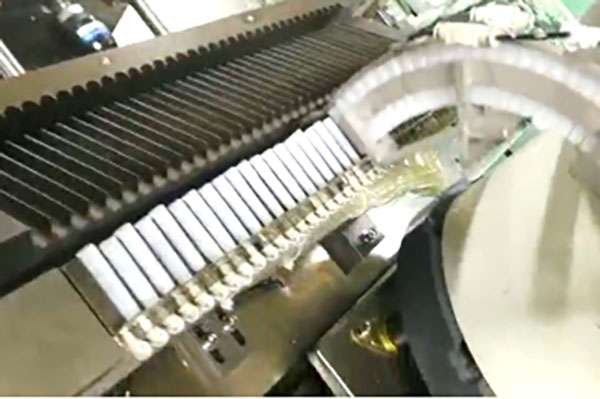

CO-hom Ntshav Drug Drishing Tshuab

Tus cwj mem-ntshav sau Hloov pauv, tuaj yeem hloov kho raws li cov kev cai tshwj xeeb, muaj ntau yam kev ua haujlwm tau xaiv tau, rau cov neeg siv khoom ua kom tau zoo thiab txhim kho ntau lawm. Muaj peev xwm ntau lawm tuaj yeem ncav cuag 12000-15000pcs / teev.

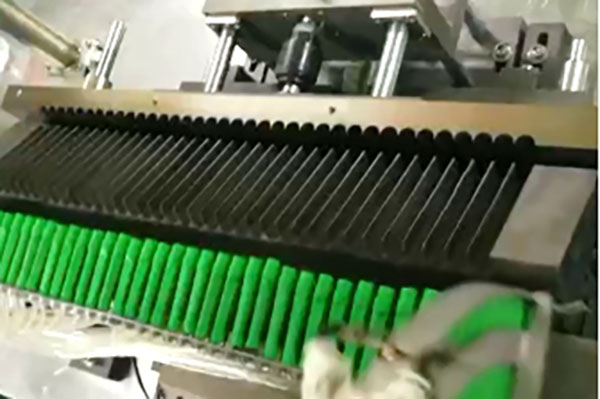

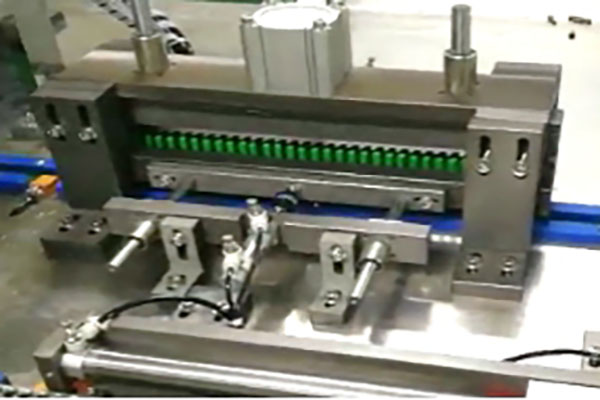

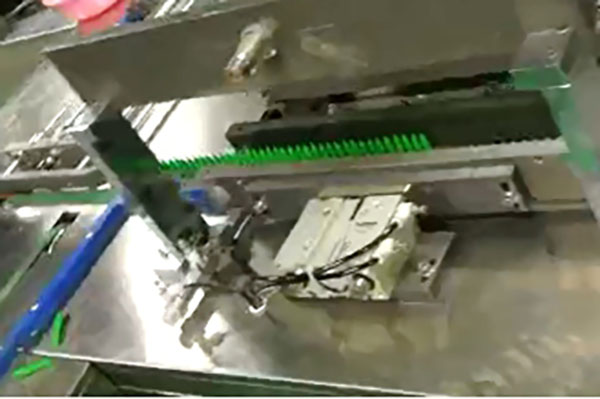

Cov cuab yeej txais tau ntau yam khoom siv ntau lub tes tsho thiab sib npaug ntawm cov txheej txheem nrawm nrawm nrawm los ua kom zoo dua cov khoom lag luam zoo. Cov haujlwm xws li kev nrhiav fiber ntau, kev ua kom tsis siv neeg thiab CCD on-kab nrhiav kom ua kom cov khoom lag luam tsim khoom thiab txhim kho ntau dua nyob rau tib lub sijhawm.

ROTDER ZERPERING → koob Kev Tshawb Xyuas → Kev Tiv Thaiv Kev Siv Hluav Taws Xob → Cov Khaub Ncaws Hnav → Cov Khaub Ncaws Hnav → Cov Khoom Siv Tawg Nrov → Npog Kev Lag Luam → Npog Kev Lag Luam Troading Detting Chaw Thau Ntawv → Testining Propecting → Tiav Cov Khoom Tiav

| Siv rab koob | Cwj mem hom |

| Ua haujlwm ceev | 12000-15000PCS / teev |

| Kev kuaj CCD kom raug qhov tseeb rau koob hmoov | 0.05 * 0.05 (Raws li ntsis qhov siab ua kom ntev li 0.3) |

| Hwjchim | 380v / 50 lossis 60Hz, 16kW |

| Compressed cua | Huv si compressed cua siab 0.6-0.8mpa |

| Cov neeg ua haujlwm ua haujlwm | 5-6 |

| Chaw Haujlwm | 6080 * 11200 * 1800 hli (l * w * h) |

| Qho hnyav | 9000kg |

| *** NCO TSEG: Raws li cov khoom yog hloov tas li, thov hu rau peb rau cov kev qhia tseeb. *** | |